1. Guud

Noocan waalka ah waxaa loogu talagalay in uu noqdo rakibaadda furan oo xiran si loo ilaaliyo hawlgalka saxda ah ee loo isticmaalo nidaamka dhuumaha warshadaha.

2. Sharaxaada Alaabta

2.1 Shuruudaha farsamada

2.1.1 Naqshadaynta iyo Heerka Wax-soo-saarka: API 600, API 602

2.1.2 Heerka cabbirka isku xirka: ASME B16.5 iwm

2.1.3 Heerka cabbirka wejiga ka waji: ASME B16.10

2.1.4 Kormeerka iyo Imtixaanka: API 598 iwm

2.1.5 Cabbirka:DN10 ~ 1200, Cadaadiska: 1.0 ~ 42MPa

2.2 Waalkan waxa uu ku qalabaysan yahay isku xidhka flange, xidhiidhka BWJirriddu waxay u socotaa jihada toosan.Saxanka iridda wuxuu xiraa dhuumaha inta lagu jiro wareegga saacadda ee taayirrada gacanta.Saxanka iriddu wuxuu furaa dhuumaha inta lagu jiro wareegitaanka taayirrada gacanta ee saacadda ka soo horjeeda.

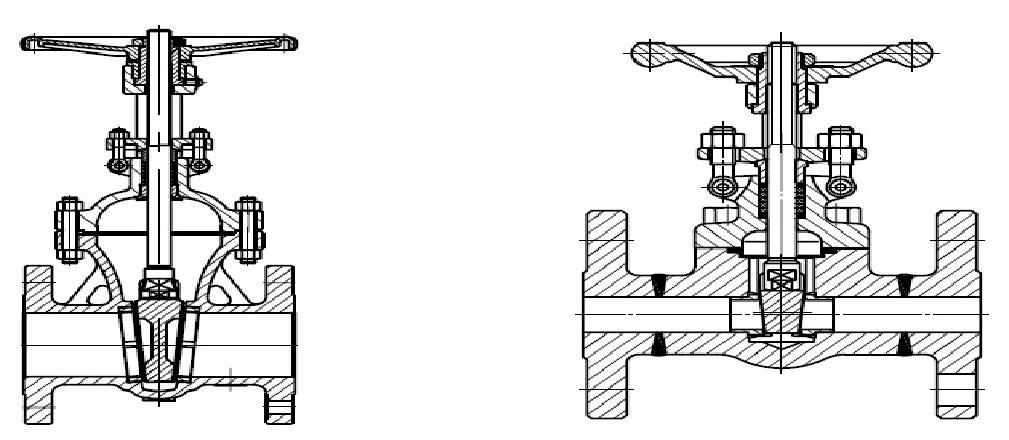

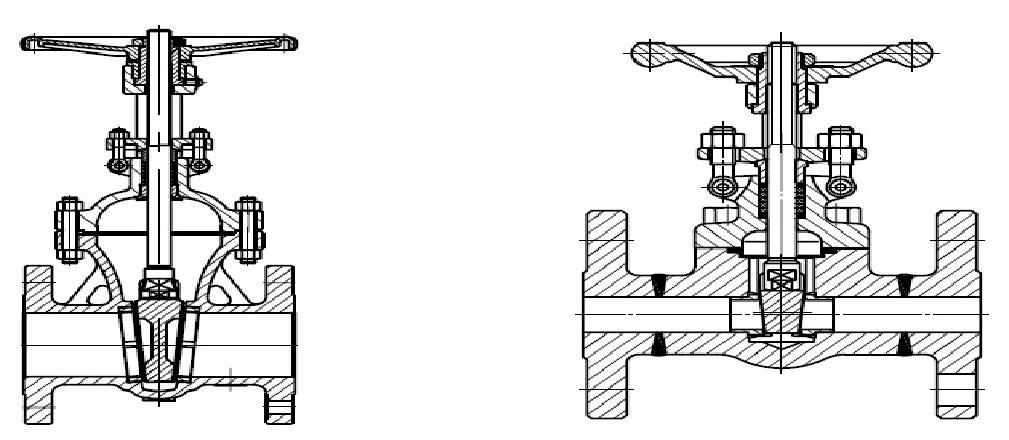

2.3 Fadlan tixraac qaabka sawirka soo socda

Sawir 1

Sawir 2

Sawir 3

Sawir 4

2.4 Qaybaha ugu muhiimsan iyo Qalabka

| MAGACA | ALAAB |

| Jirka/Bonnet | WCB,LCB,WC6,WC9,CF3,CF3M CF8,CF8M |

| Albaabka | WCB,LCB,WC6,WC9,CF3,CF3M CF8,CF8M |

| Kursiga | A105,LF2,F11,F22,F304(304L),F316(316L) |

| Jirrid | F304(304L),F316(316L),2Cr13,1Cr13 |

| Baakad | Garaafka tidcan & Garaafka dabacsan & PTFE iwm |

| Bolt/Nut | 35/25,35CrMoA/45 |

| Gasket | 304(316)+Grafit /304(316)+Gaaska |

| Kursiga Garaac/Diis /Shaabadeynta | 13Cr,18Cr-8Ni,18Cr-8Ni-Mo,PP,PTFE,STL iwm |

3. Kaydinta & Dayactirka & Rakibaadda & Hawlgalka

3.1 Kaydinta & Dayactirka

3.1.1 Valves waa in lagu kaydiyaa xaalada gudaha.Cidhifyada godka waa in lagu daboolaa fig.

3.1.2 Baadhitaanka iyo nadiifinta wakhtiyeedka ah ayaa loo baahan yahay wakhti dheer alwaaxyada kaydsan, gaar ahaan daboolida nadiifinta dusha sare.Wax dhibaato ah lama ogola.Dahaarka saliidda ayaa la codsadaa si looga fogaado miridhku si loogu farsameeyo dusha sare.

3.1.3 Ku saabsan kaydinta waalka in ka badan 18 bilood, tijaabooyin ayaa loo baahan yahay ka hor inta aan la rakibin waalka oo la diiwaangeliyo natiijada.

3.1.4 Valves waa in si joogto ah loo baaro oo la dayactiro ka dib marka la rakibo.Qodobbada ugu muhiimsan waa sida soo socota:

1) dusha daboolida

2) Dhirta iyo jirida

3) Baakadaha

4) Nadiifinta dusha gudaha ee Jirka iyo Bonnetka.

3.2 Rakibaadda

3.2.1 Dib u hubi calamadaha waalka (Nooca, DN, Rating, Material) kaas oo u hogaansama calaamadaha lagu codsado nidaamka dhuumaha.

3.2.2 Nadiifinta buuxda ee daloolka iyo daboolida dusha sare ayaa la codsadaa ka hor inta aan la rakibin waalka.

3.2.3 Hubi in boolalku ay adag yihiin ka hor inta aan la rakibin.

3.2.4 Hubi in baakadu ay adag tahay ka hor inta aan la rakibin.Si kastaba ha ahaatee, waa inaysan carqaladayn dhaqdhaqaaqa stem.

3.2.5 Goobta Valve waa inay ku habboonaato kormeerka iyo hawlgalka.Horizontal to pipeline ayaa la door bidayaa.Kor u qaad shaagaga gacanta iyo jirida mid taagan.

3.2.6 Qalabka xiritaanka, kuma habboona in lagu rakibo xaalad shaqo oo cadaadis sare leh.Jirriddu waa in laga fogaadaa in ay dhaawacdo.

3.2.7 Waalka alxanka Socket, dareenka ayaa la codsanayaa inta lagu jiro isku xirka valve sida soo socota:

1) Welder waa in la shahaado.

2) Halbeegga habka alxanka waa in uu ahaadaa mid waafaqsan shahaado tayada alxanka qaraabo.

3) Walxaha buuxinta ee xariiqda alxanka, kiimikooyinka iyo waxqabadka farsamada oo ay weheliso daxalka ka hortagga waa inay la mid noqdaan walxaha waalidka.

3.2.8 Ku rakibida Valve waa in ay ka fogaato cadaadiska sare ee lifaaqyada ama tuubooyinka.

3.2.9 Kadib rakibidda, valves waa inay furnaadaan inta lagu jiro tijaabada cadaadiska tuubada.

3.2.10 Taageerada Point: haddii dhuunta ay tahay mid xoogan oo ku filan si ay u taageeraan miisaanka waalka iyo torque hawlgalka, barta taageerada lama codsan.Haddii kale waa loo baahan yahay.

3.2.11 Qaadista: Qaadista taayirrada gacanta looma oggola valves.

3.3 Hawlgalka iyo Isticmaalka

3.3.1 Albaabada albaabadu waa inay si buuxda u furnaadaan ama xidhaan inta lagu jiro isticmaalka si looga fogaado xirashada giraanta iyo dusha saxanka ee ay keento dhexdhexaad xawaare sare leh.Looma dacwayn karo nidaaminta socodka

3.3.2 Taayirrada gacanta waa in lagu beddelaa aaladaha kale si loo furo ama loo xiro furayaasha

3.3.3 Inta lagu jiro heerkulka adeegga la oggol yahay, cadaadiska degdegga ah waa inuu ka hooseeyaa cadaadiska la qiimeeyay marka loo eego ASME B16.34

3.3.4 Wax dhaawac ah ama shaqo joojin ah lama ogola inta lagu jiro gaadiidka waalka, rakibaadda iyo hawlgalka.

3.3.5 Qalabka cabbirka si loo hubiyo socodka aan xasilloonayn ayaa la codsanayaa si loo xakameeyo oo looga takhaluso qodobka burburay si looga fogaado burburka iyo daadinta.

3.3.6 Uumiga qabow wuxuu saameyn doonaa waxqabadka valve, iyo qalabka cabbiraadda waa in la isticmaalo si loo yareeyo heerkulka socodka ama lagu beddelo valve.

3.3.7 Dheecaan is-bari kara, isticmaal qalabka cabbiraadda habboon si loo dammaanad qaado cadaadiska deegaanka iyo shaqada kama badna barta shidista (gaar ahaan ogaysii qorrax ama dabka dibadda).

3.3.8 Haddii ay dhacdo dareere khatar ah, sida walxaha qarxa, gubanaya, sunta, alaabada oksaydhka, waa mamnuuc in la beddelo baakadaha cadaadiska.Si kastaba ha ahaatee, xaalad degdeg ah, laguma talinayo in la beddelo baakadaha cadaadiska (inkasta oo waalka uu leeyahay shaqo noocaas ah).

3.3.9 Hubi in dareeruhu aanu wasakh ahayn, kaas oo saameeya waxqabadka valve, oo aanay ku jirin adkaha adag, haddii kale qalabka cabbiraadda ku habboon waa in la isticmaalo si looga saaro wasakhda iyo adkaha adag, ama lagu beddelo nooc kale oo waalka ah.

3.3.10 Heerkulka shaqada ee lagu dabaqi karo.

| Qalab | Heerkulka | Qalab | Heerkulka |

| WCB | -29~425℃ | WC6 | -29~538℃ |

| LCB | -46~343℃ | WC9 | --29~570℃ |

| CF3(CF3M) | -196~454℃ | CF8(CF8M) | -196~454℃ |

3.3.11 Hubi in shayga valve body uu ku haboon yahay in loo isticmaalo daxalka u adkaysta iyo miridhku ka hortagayo deegaanka dareeraha.

3.3.12 Inta lagu jiro xilliga adeegga, hubi waxqabadka shaabadeynta sida ku cad shaxda hoose:

| Barta kormeerka | Daadin |

| Xidhiidhka ka dhexeeya jidhka waalka iyo bowdada | Eber |

| Shaabadda xiridda | Eber |

| Kursiga jirka ee Valve | Sida ku cad qeexitaanka farsamada |

3.3.13 Si joogto ah u hubi xirashada qiimaha fadhiga, baakad gabow iyo burbur.

3.3.14 Dayactir ka dib, dib isugu soo ururi oo hagaaji waalka, ka dibna tijaabi waxqabadka cidhiidhiga oo samee diiwaan.

4. Dhibaatooyinka suurtagalka ah, sababaha iyo tallaabooyinka lagu saxayo

| Sharaxaada dhibka | Sabab macquul ah | Tallaabooyinka hagaajinta |

| Ka daadato xirashada | Baakad aan ku filnayn | Dib u adkee lawska baakadaha |

|

| Baakad aan ku filnayn | Ku dar baakad badan |

|

| Baakadaha dhaawacan sababtoo ah adeeg waqti dheer ah ama ilaalin aan habboonayn | Beddel baakadaha |

| Ka daadanaya wajiga fadhiga valve | Waji fadhi wasakh ah | Ka saar wasakh |

|

| Wejiga fadhiga oo duugoobay | Dayactir ama beddel giraanta fadhiga ama saxanka |

|

| Wejiga fadhiga oo waxyeeloobay sababtoo ah adkaha adag | Ka saar walxaha adag ee dareeraha ah, ku beddel giraanta fadhiga ama saxanka, ama ku beddel nooc kale oo waalka ah |

| Diidida xidhiidhka ka dhexeeya jidhka waalka iyo bowdada | Boolasha si fiican looma xidhin | Si caadi ah u xidh boolal |

|

| Wejiga xidhidhiyaha baaldiga ah ee dhaawacan | Dayactir |

|

| Burbursan ama jaban | Beddel gasket |

| Wareegtada adag ee taayirrada gacanta ama saxanadda valve lama furi karo lamana xidhi karo. | Baakad aad u adag | Looska baakadaynta si habboon u furfur |

|

| Qallooca ama laablaabashada qanjidhka xidhida | Hagaajin qanjidhada daboolaya |

|

| lowska jirridda waalka oo burburay | Dunta saxda ah oo ka saar wasakhda |

|

| dunta tarigga waalka oo xidhan ama jabay | Beddel lawska stem lawska |

|

| Laabsan jirida waalka | Beddel jiridda waalka |

|

| Dusha hagaha wasakhda ah ee saxanka valve ama jirka | Ka saar wasakh dusha hagaha |

Fiiro gaar ah: Qofka adeeguhu waa inuu lahaadaa aqoon iyo waayo-aragnimo la xidhiidha valves-ka biyaha xidhidhiyaha albaabka

Xirmooyinka bonnetka waa qaab dhismeedka daboolida biyaha, waxaa laga sooci doonaa hawada halka cadaadiska biyuhu uu gaaro 0.6 ~ 1.0MP si loo dammaanad qaado waxqabadka wanaagsan ee xiritaanka hawada.

5.Dammaanad:

Ka dib markii waalka la geliyo, muddada dammaanadda ee waalka waa 12 bilood, laakiin kama badna 18 bilood ka dib taariikhda dhalmada.Inta lagu jiro muddada dammaanadda, soo-saaruhu waxa uu ku siin doonaa adeeg dayactir ama qalab-hagaajin lacag la'aan ah waxyeelada ay sabab u tahay agabka, shaqada ama burburka waa haddii hawlgalku sax yahay.

Waqtiga boostada: Meey-19-2022