1. Baaxadda

Noocyada DN waxaa ka mid ah DN15mm ~ 600mm (1/2 "~ 24") iyo PN waxay u dhexeeyaan PN1.6MPa ~ 20MPa (ANSI CLASS150 ~ 1500) dunta, flanged, BW iyo SW lulid iyo kor u qaadida jeegga jeegga.

2.Isticmaalka:

2.1 Waalkani waa inuu ka hortago socodka dhexdhexaadka ah ee nidaamka tuubada.

2.2 Qalabka Valve waxaa lagu doortaa si dhexdhexaad ah.

2.2.1WCB valve wuxuu ku habboon yahay biyaha, uumiga iyo saliidda dhexdhexaadka ah iwm.

2.2.2SS valve wuxuu ku habboon yahay dhexdhexaadinta daxalka.

2.3 Heerkul:

2.3.1WCB Common waxay ku haboon tahay heerkulka -29 ℃ ~ +425 ℃

2.3.2 Alloy valve wuxuu ku habboon yahay heerkulka ≤550 ℃

2.3.3SS waalka ku haboon heerkulka-196 ℃ ~ + 200 ℃

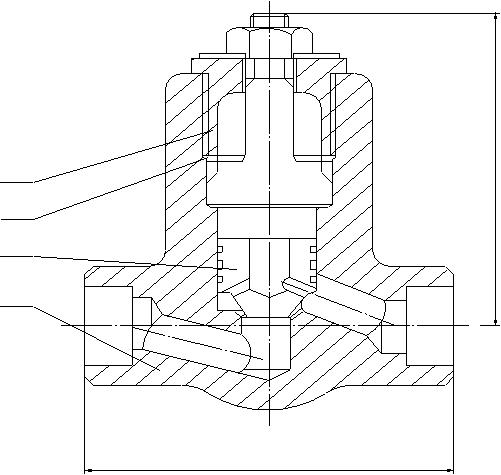

3. Qaab dhismeedka iyo sifooyinka waxqabadka

3.1 Qaab dhismeedka aasaasiga ah waa sida hoose:

3.2 PTFE iyo graphite dabacsan ayaa loo qaataa gaasaska waxyeelaysan kara si loo hubiyo waxqabadka xidhidhiyaha.

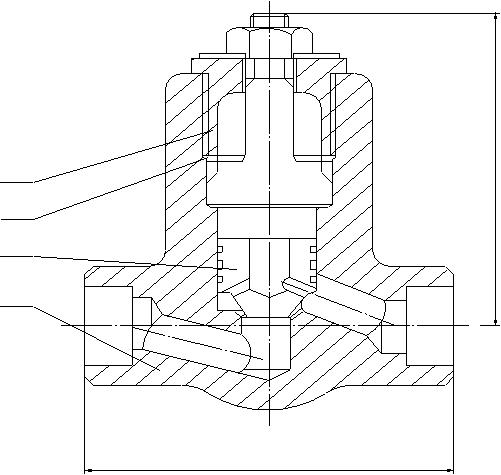

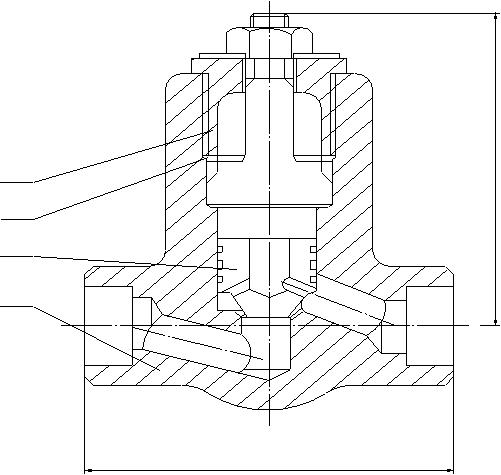

(A) Alxanka been abuurka ah ee cadaadiska sare ee is-xakamaynta waalka hubinta

(B) Alxanka foornada ee jeegga jeegga

1.jirka 2. disc 3. gasket 4. bonnet

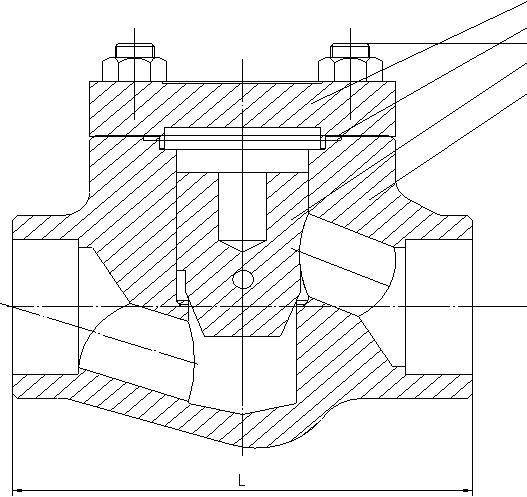

(C) Qalabka Hubinta Qaadista BW

(D) Valve Check Flanged

1.Body 2. Disc 3. Shaft 4. Gasket 5. Bonnet

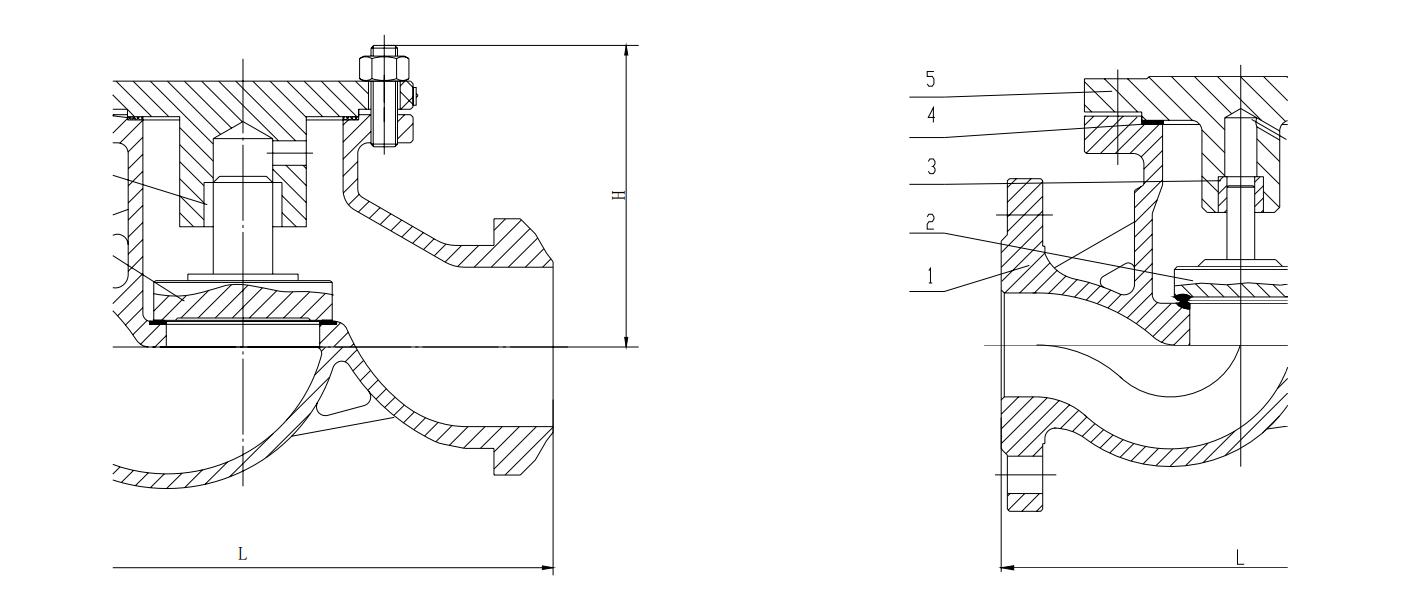

(E) BW Swing Check Valve

(F) Hubinta Lulid Flanged

1.Jidhka 2. Kursiga 3. Saxanka 4. Gacan-gacan 5. Shaft Pin 6. Harqood 7. Gasket 8. Bonnet

3.3 Qalabka ugu muhiimsan

| Magaca | Qalab | Magaca | Qalab |

| Jirka | Birta Kaarboon, SS, Daawaha Birta | Shaft Pin | SS, Cr13 |

| Kursiga Seal | Dusha sare ee 13Cr, STL, caag | Harqood | Birta Kaarboon, SS, Daawaha Birta |

| Saxanka | Birta Kaarboon, SS, Daawaha Birta | Gasket | PTFE, Graphite dabacsan |

| Gacan Rocker | Birta Kaarboon, SS, Daawaha Birta | Bonnet | Birta Kaarboon, SS, Daawaha Birta |

3.4 Shaxda Waxqabadka

| Qiimaynta | Imtixaanka xoogga (MPa) | Imtixaanka shaabadda (MPa) | Imtixaanka shaabadda hawada (MPa) |

| Fasalka150 | 3.0 | 2.2 | 0.4 ~ 0.7 |

| Fasalka 300 | 7.7 | 5.7 | 0.4 ~ 0.7 |

| Fasalka 600 | 15.3 | 11.3 | 0.4 ~ 0.7 |

| Fasalka 900 | 23.0 | 17.0 | 0.4 ~ 0.7 |

| Fasalka1500 | 38.4 | 28.2 | 0.4 ~ 0.7 |

| Qiimaynta | Imtixaanka xoogga (MPa) | Imtixaanka shaabadda (MPa) | Imtixaanka shaabadda hawada (MPa) |

| 16 | 2.4 | 1.76 | 0.4 ~ 0.7 |

| 25 | 3.75 | 2.75 | 0.4 ~ 0.7 |

| 40 | 6.0 | 4.4 | 0.4 ~ 0.7 |

| 64 | 9.6 | 7.04 | 0.4 ~ 0.7 |

| 100 | 15.0 | 11.0 | 0.4 ~ 0.7 |

| 160 | 24.0 | 17.6 | 0.4 ~ 0.7 |

| 200 | 30.0 | 22.0 | 0.4 ~ 0.7 |

4. Aragtida shaqada

Hubi waalka si otomaatig ah ayuu u furmaa oo xiraa saxanka si looga hortago socodka dhexdhexaadka ah ee socodka dhexdhexaadka ah.

5. Heerarka valve ee lagu dabaqi karo laakiin kuma koobna:

(1) API 6D-2002 (2) ASME B16.5-2003

(3) ASME B16.10-2000 (4)API 598-2004

(5) GB/T 12235-1989 (6) GB/T 12236-1989

(7) GB/T 9113.1-2000 (8) GB/T 12221-2005 (9)GB/T 13927-1992

6. Kaydinta & Dayactirka & Rakibaadda & Hawlgalka

6.1 Waalka waa in lagu kaydiyaa qol qallalan oo hawo fiican leh.

6.2 Waa in si joogto ah loo baaro oo loo nadiifiyaa Valves-ka ku jira kaydinta muddada dheer, gaar ahaan wajiga fadhiga si looga hortago in uu waxyeelo soo gaadho, iyo in wajiga fadhiga lagu dahaadhi karo miridh ka ilaalinaya saliidda.

6.3 Calaamadaynta Valve waa in la hubiyaa si loo waafajiyo isticmaalka.

6.4 Godka Valve iyo dusha daboolida waa in la hubiyaa ka hor inta aan la rakibin oo ka saar wasakh haddii ay jirto.

6.5 Jihada fallaadha waa inay la mid noqotaa jihada socodka.

6.6 Qaadista valve hubinta saxanka toosan waa in si toosan loogu rakibaa dhuumaha.Qaadista waalka hubinta saxanka jiifka ah waa in lagu rakibaa si toos ah dhuumaha.

6.7 Gariirka waa in la hubiyaa iyo isbedelka cadaadiska dhexdhexaadka ah ee dhuumaha waa in la ogaadaa si looga hortago saameynta biyaha.

7.Dhibaatooyinka suurtagalka ah, sababaha iyo cabbirka hagaajinta

| Dhibaatooyinka suurtagalka ah | Sababaha | Qiyaasta Sixitaanka |

| Saxanku ma furi karo mana xidhi karo |

| |

| Diidashada |

| |

| Buuq iyo Gariir |

|

8. Dammaanad

Ka dib markii waalka la geliyo, muddada dammaanadda ee waalka waa 12 bilood, laakiin kama badna 18 bilood ka dib taariikhda dhalmada.Inta lagu jiro muddada dammaanadda, soo-saaruhu waxa uu ku siin doonaa adeeg dayactir ama qalab-hagaajin lacag la'aan ah waxyeelada ay sabab u tahay agabka, shaqada ama burburka waa haddii hawlgalku sax yahay.

Waqtiga boostada: Meey-19-2022